| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | KEYE |

| Model Number : | KVIS-B |

| Certification : | NO |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T |

| Delivery Time : | 4 to 6 weeks |

| System operating parameters | |||

| Size | See the details from draw | Voltage | 220V 20A 50HZ |

| Power | 5.0-6.0kw | Compressed air | 0.5~0.8MPa Purify and oil-free |

| Environment temperature | -20℃ ~ 60℃ | Environment humidity | Below 50% relative humidity |

As a very popular decorative material, wallpaper is widely used in various occasions such as home improvement and tooling.In the production process of wallpaper, due to the production process and the impact of the on-site environment, it is easy to cause various tiny flaws on the surface of the wallpaper, and the wallpaper is a larger product material. If a little bit of problem occurs, and the entire wallpaper will cause very serious problems can cause Big waste,Therefore, these deficiencies not only affect the appearance of the wallpaper, but more importantly, it reduces the performance of the wallpaper.

People are now demanding higher and higher quality of life, the traditional manual visual detection method can no longer meet the high speed of modern production. For high-efficiency and non-destructive intelligent detection requirements, Keye Technology has launched a wallpaper surface visual detection system, which has the advantages of faster, reliable and higher accurate compared with traditional artificial eye detection.

【working principle】

When the production line is in normal production, the bright LED linear light source uses the transmission principle to illuminate the product surface (for paper products with thicker paper and higher surface defect detection angles, the use the reflection detection principle), and the linear array is set up on the production line The camera performs real-time synchronous scanning, and the system passes the paper defect image collected by the camera through the KVS image processing unit for defect segmentation processing.

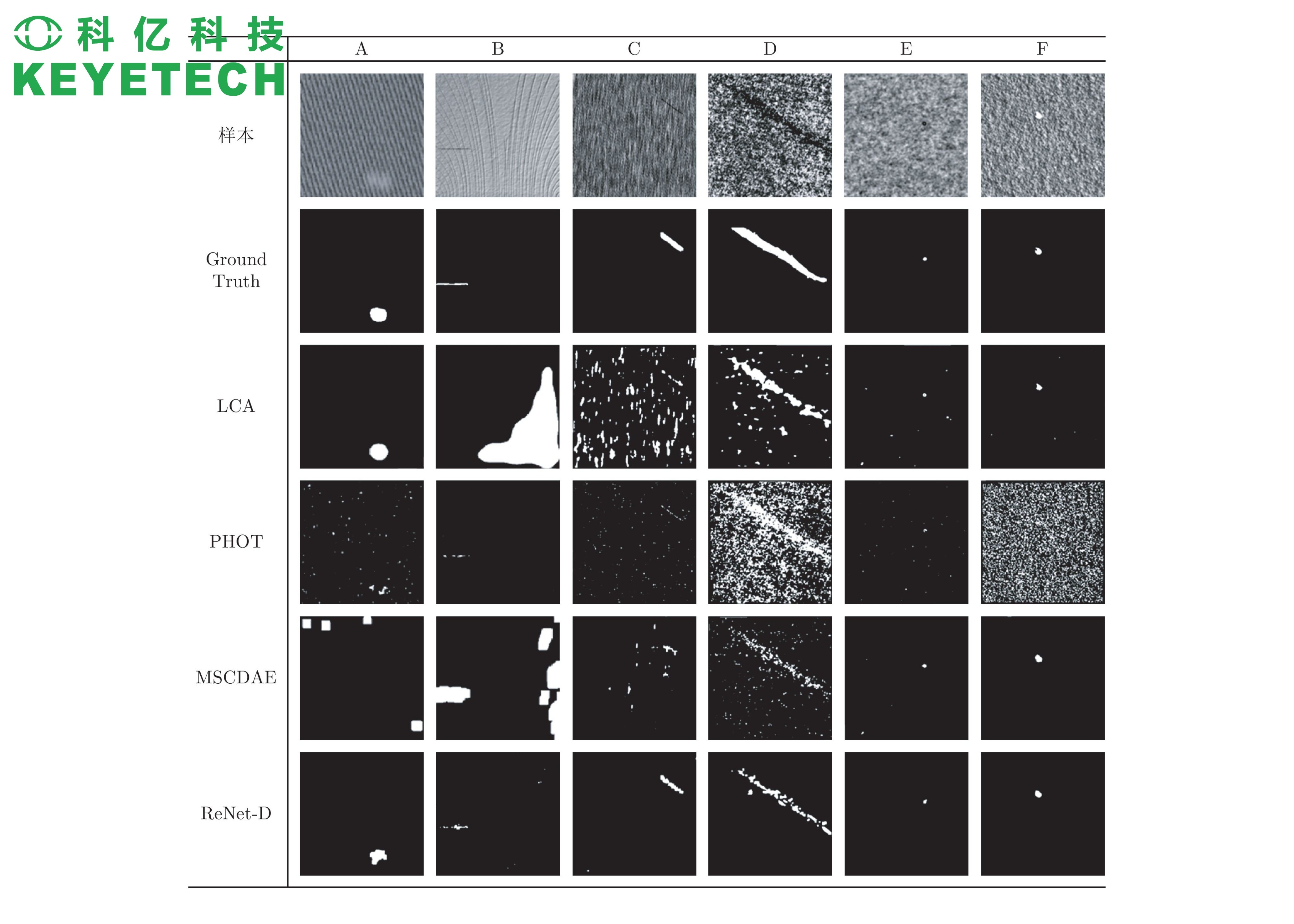

Due to the obvious difference between the gray scale of the flawed image and the gray scale of the normal product, the AI artificial intelligence algorithm is used to enable the system to find and locate the flaws accurately, effectively judge and classify the flaws at the same time.

Detected defects are as follows:

|