| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | KEYE |

| Model Number : | KVIS-B |

| Certification : | NO |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T |

| Delivery Time : | 4 to 6 weeks |

| Supply Ability : | 1 set per 6 weeks |

Equipment features:

| 1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3.Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4.High precision: detection accuracy can be high |

| 5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6.Easy to operate: It is easy to operate and easy to maintain |

| 7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Product background:

Tarpaulin is the main material for the cover of automobile transportation and open-air storage and tents in the field. It is usually divided into two categories: coarse canvas and fine canvas. The surface quality of the canvas will directly affect the quality of the finished product and the safety of the later users.Now the current domestic production environment and production process of non-woven fabrics, it is easy to cause defects in processing ,such as mosquitoes, black spots, metal iron filings, stains, slurries, and impurities on the surface of the material. Due to the fast production speed and small flaws of the product, the traditional artificial eye detection cannot meet the quality standards . The canvas tarpaulin surface defect detection system of Keye can perform all-weather ,high-speed and high-speed operation on the high-speed canvas tarpaulin production line. Accurate online detection of surface defects.

The product principle:

The canvas and tarpaulin surface defect detection system sets up a linear CCD camera above the production line. The camera is triggered to obtain image information ,resolution of the camera ,determines the image sampling accuracy of the product through an encoder connected to the drive shaft of the workshop. The system has high precision and large amount of image data processing. After the data is processed at a high speed, the product defect data information is retained and the control signal is output. The computer system records and manages the specific location, size, image and other information of the defect through the database.

Detection object:

Canvas, PE tarpaulin, PVC tarpaulin

Technical parameters:

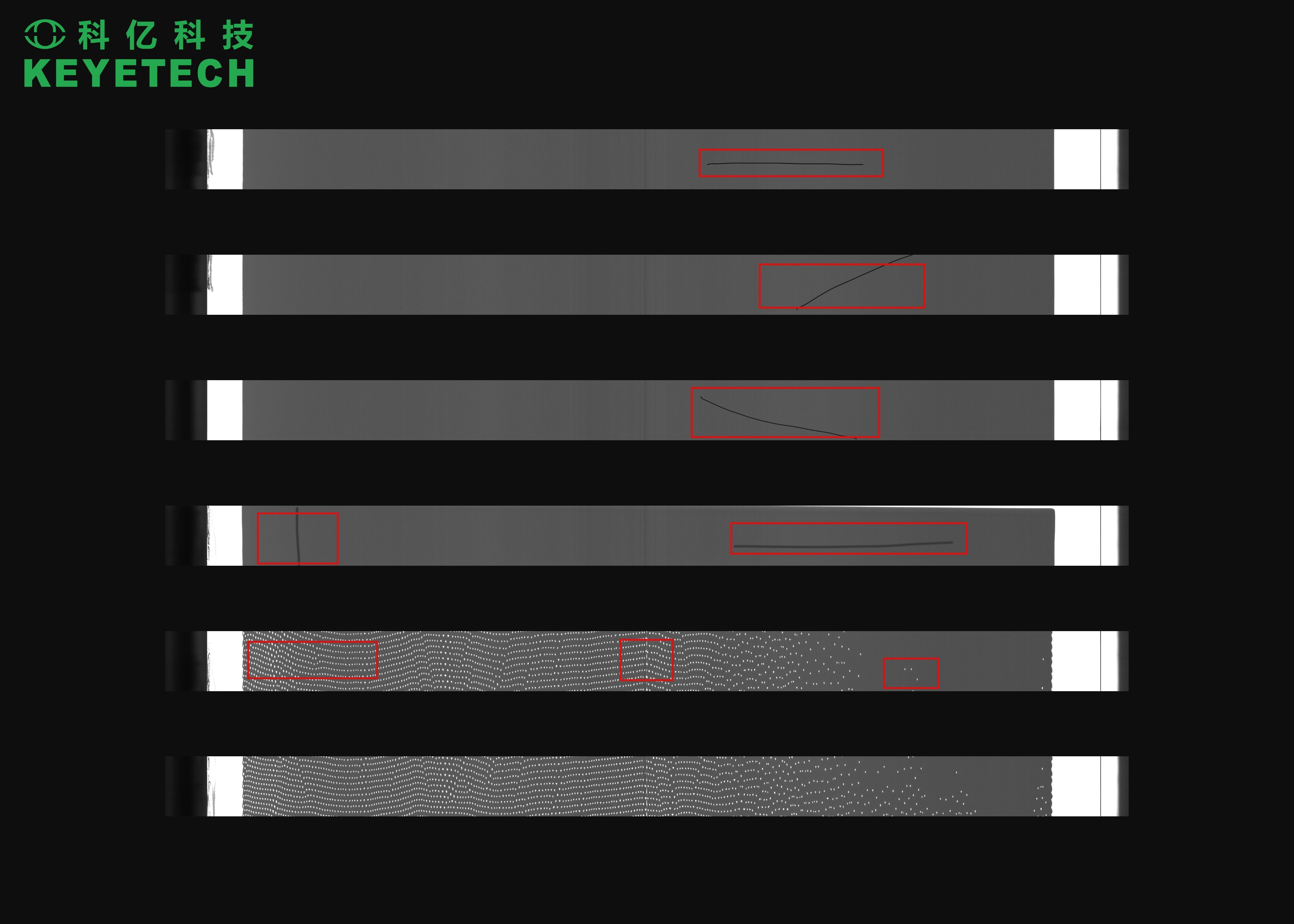

Typical defects: stains, nodes, mosquitoes, foreign bodies, oil stains, wrinkles, fibers, etc.;

Detection width: any width (a variety of widths can be met by the combination of camera types and numbers);

Detection speed: maximum 200m/min;

Detection accuracy: Determined according to the width of the production line and the configuration of the camera;

Defect feedback: sound and light alarm, real-time labeling, real-time display of defect coordinate information distribution map, quality report, etc.

System advantages:

1 >> High-speed industrial camera + innovative modular design, suitable for various production line width, line speed and resolution requirements, providing different kind of equipment communication interfaces, seamless docking with field line control ,industrial robots and other equipment;

2 >> Multi-field and multi-light source imaging technology can accurately measure the core size and deformation size of defects, with high classification accuracy;

3 >> High-speed embedded real-time image processing and feature extraction technology to ensure a very low rate of missed detection and false detection of the system;

4 >> Deep learning and other artificial intelligence defect recognition technology, real-time matching with the company's canvas and tarpaulin industry database;

5 >> Intuitive visualization software, observe the flaws in realistic, high-resolution 2D images;

6 >> SQL database system for easy access to production data, real-time query and traceability of product performance indicators;

7 >> Provide remote software system upgrades and remote maintenance management, laying the foundation for factory intelligent and unmanned management;

8 >> Convenient on-site maintenance, the light source can be moved and pushed as a whole system, and there is no need to calibrate again after maintenance;

9 >> Equip with the water cooling system to allow the equipment to operate stably at high speed for a long time under constant temperature conditions.

Test example:

|