| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

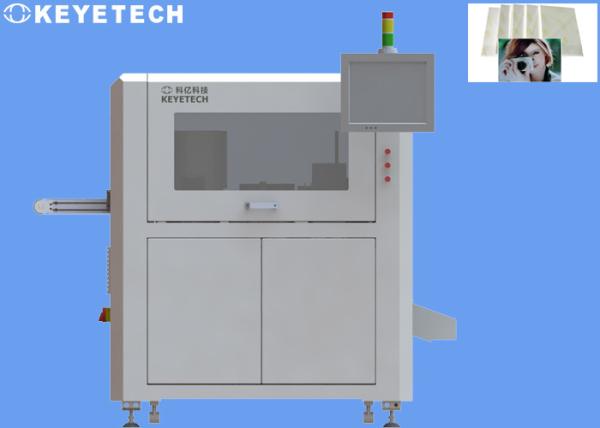

| Brand Name : | KEYE |

| Model Number : | KVIS-B |

| Certification : | NO |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T |

| Delivery Time : | 4 to 6 weeks |

System details

| Detection standard | Scratches, thorns, lifts or black spots |

| Voltage | Adapt to customer's national standards |

| Environment temperature | -10℃~+45℃ |

| Environment humidity | Below 85% (no condensation) |

| SIZE | 1100*620*1160 |

| ODM/OEM | Accept |

Inspection principle

At present, photo paper is widely used in the field of professional image output such as wedding photography and children's photography in the market; there are also used as advertising materials, menus, business cards, resumes, and various public fields.Photo paper is not an industry well-known to the public, but related industries are absolutely inseparable from it.However,during the production of photographic paper, due to the influence of the production process and the on-site environment, it is easy to cause defects such as scratches, thorns, lifting or black spots on the surface of the photographic paper.

These defects not only affect the appearance of paper products, but more importantly, reduce the performance of the paper.But the traditional detection methods such as manual visual detection are far from being able to meet the requirements of high-speed, high-resolution, and non-destructive intelligent inspection in current industrial production.Keye Technology has launched a photo paper surface visual detection system, which has the advantages of fast, reliable and accurate compared with the traditional artificial eye detection.

Detection type:

Glossy photo paper, suede photo paper, sub-glossy photo paper, professional photo paper, matt photo paper, adhesive photo paper, etc.

Detection size:

17'X30m, 18'X30m, 24'X30m, 42'X30m, 44'X30m. (Photo paper has 6 inch (A6), 7 inch (A7), 1 inch (cut), 2 inch (cut), A4, A3, etc.

Detection weight:

Weight per square meter: generally 130g-180g, of which 150g-180g is widely used

Product Principle:

The canvas and tarpaulin surface defect detection system sets up a linear CCD camera above the production line. The camera is triggered to obtain image information ,resolution of the camera ,determines the image sampling accuracy of the product through an encoder connected to the drive shaft of the workshop. The system has high precision and large amount of image data processing. After the data is processed at a high speed, the product defect data information is retained and the control signal is output. The computer system records and manages the specific location, size, image and other information of the defect through the database.

Examples of equipment detection defects:

Advantages of system

|