| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | KEYE |

| Model Number : | KVIS-T |

| Certification : | NO |

| Price : | Negotiable |

| Payment Terms : | L/C, T/T |

| Delivery Time : | 4 to 6 weeks |

The detection performance is as follows:

| Model | Number Cameras | Detection range | Detection content and accuracy | Detection standard | Detection accuracy | Detection speed |

| KVIS-C-SC013 | 1 Set | Top of cone yarn | Large area dirt | dirt>0.5mm | 99.5% | 60piece/min |

| Circular trace | wide>5mm | |||||

| Step bulge | wide>5mm | |||||

| Net yarn, pantou | wide>5mm | |||||

| Chrysanthemum core | wide>5mm | |||||

| Small end winding yarn | wide>5mm | |||||

| 12Sets | Cone yarn Around | Large area dirt | dirt>0.5mm | |||

| Depression in middle of bobbin | wide>5mm | |||||

| Random yarn | wide>5mm | |||||

| Ribbon yarn | wide>5mm | |||||

| Return Yarn | wide5mm | |||||

| Winding yarn | wide>5mm | |||||

| Steps in the middle of the bobbin | wide>5mm |

General condition of detection system.

The whole machine integrates mechanical mechanism, visual optical hardware and detection system software, defective product elimination and counting device.The detection speed is subject to the matching on-site speed. The inlet and outlet of the detector can be connected with the customer's transmission line.The machine can 7 * 24-hour running, which greatly improves the production efficiency.

The detector equipped with 13 sets of high-pixel industrial cameras and lenses (the number of cameras is determined by the product specification). The defects on the top of the cone yarn and around the corn yarn are comprehensively detected(As the special nature of the product shape, the scheme does not consider testing the lower bottom surface of the cone yarn temporarily. If testing is required, a set of mechanical structure needs to be updated),After the system collects the sample image, through the comparative analysis of image processing software and standardized sample, good products and bad products are determined, the detected bad products are automatically removed, and the counting function can be realized after the finished product is detected. The software will show the sample comparison standard, and the production person on customer's site can control the comparison accuracy and select the accuracy standard most suitable for their own production , so as to control the defect rate.

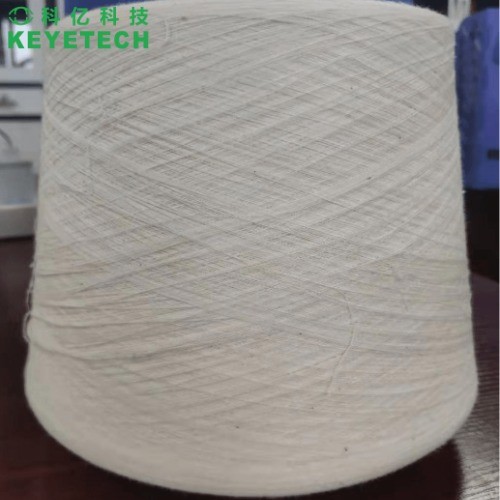

Sample:

Detection content and accuracy

Advantages of system:

|